Ecology

Ceramic substrates for automotive catalytic converters

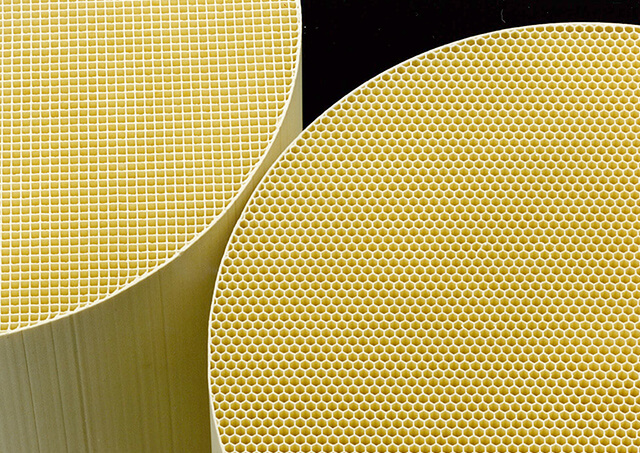

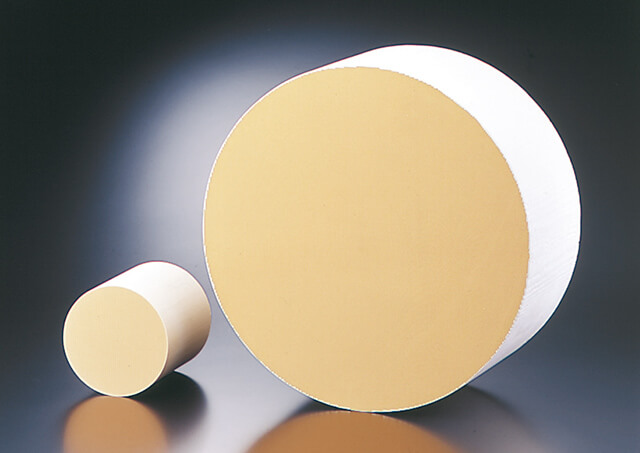

HONEYCERAM

NGK Insulators’ fine ceramic technology appreciated by worldwide automotive manufacturers.

HONEYCERAM is a ceramic catalyst carrier, which neutralizes the harmful substances in automotive exhaust. HONEYCERAM’s honeycomb design results in a large surface area—the area that comes into contact with exhaust—with a very compact installation. In fact, the coating of gas-purifying catalyst total surface on a palm-size HONEYCERAM would cover an area equivalent to two soccer grounds. For maximum exhaust gas cleaning efficiency, HONEYCERAM was designed with minimum weight and wall thickness: the 0.05 mm walls minimize loss of engine power. The remarkable properties of cordierite ceramics—of which HONEYCERAM is—enable it to withstand the high temperatures as well as sudden and sharp temperature changes of exhaust gas with ease.

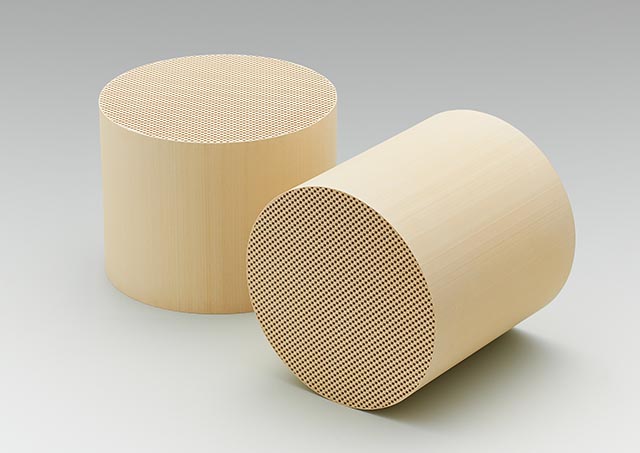

Diesel particulate filters

Gasoline particulate filters

Developing purification technologies designed to meet stricter exhaust gas regulations and help preserve the environment.

As the world hurries to regulate diesel exhaust gases, NGK group has been busy developing a range of state-of-the-art products designed to satisfy stringent new standards. Diesel particulate filters (DPF) incorporating our porous ceramic filter technologies are effective in catching particulate matter (PM) in their fine pores. As the only manufacturer to mass-produce two kinds of diesel particulate filters, cordierite and silicon carbide, we use our ceramic technologies to support even cleaner diesel vehicle emissions. We also offer gasoline particulate filters that remove particulate matter emitted from direct-injection gasoline engines, as we continue to respond to rapidly-evolving environmental requirements worldwide.

Featuring superior heat resistance, silicon carbide filters are used in passenger cars, while lightweight cordierite filters are used mainly in heavy duty vehicles.

NOx sensors

The world's first sensor capable of measuring real-time NOx concentrations in vehicle exhaust.

Our in-vehicle high-precision NOx sensor is the world's first vehicle-mounted sensor capable of measuring the concentration of NOx (nitrogen oxide) contained in automotive exhaust gas at the ppm (parts per million) level. Measuring real-time NOx concentrations and feeding back that information to the engine controls enables precise control of the exhaust gas purification system to reduce NOx emissions. The zirconia-based ceramic element, which passes oxygen ions when a voltage is applied under high temperatures, can be inserted directly into high-temperature exhaust gases and exhibits both superior responsiveness and stable long-term performance. In response to more stringent regulations on marine vessel exhaust gases, the sensor is increasingly being utilized for monitoring and reducing NOx concentration in vessel exhaust gas purification systems as well.

Industrial process products

Groundbreaking ceramic technologies for industries hungry for innovation.